Work better dust-free

The problem: Whether on a construction site, in a company or in the private sphere - drilling, milling, grinding or sawing often results in very high dust emissions.

The danger: Without appropriate protective measures, the smallest dust particles produced in the process are inhaled. In the worst case, they penetrate into the alveoli of the lungs, where they can cause the greatest damage.

The ideal solution: Preventing dust formation in good time - by using powerful starmix high-performance power tool vacuum cleaners.

Your advantage: They extract dust particles with intelligent pulse filter cleaning directly at the power tool.

Dust in Detail

No matter where work is done - dust is generated almost everywhere. That's why it's important to know what dangers can arise. They range from mildly to moderately to highly hazardous classified dusts. At high levels of exposure, they often lead to illness - in extreme cases even to lung cancer. In our handbook "Hazardous Dust" you will learn everything about prevention and safety when it comes to dust.

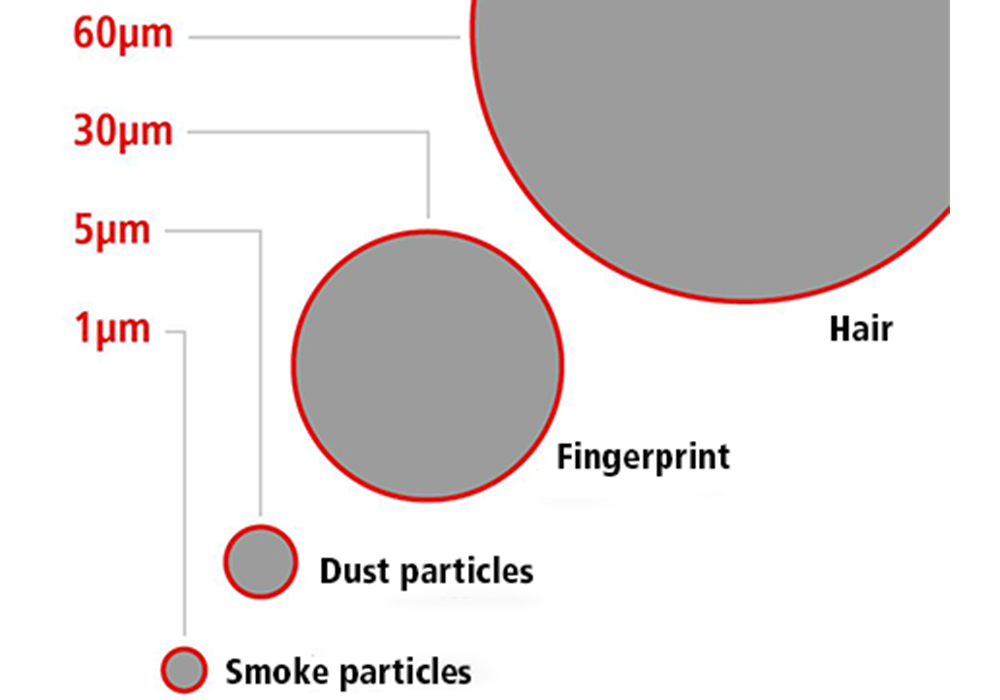

Finer is meaner!

Dust is the collective term for the finest solid particles with a maximum size of 1 mm. Dust arises naturally, e.g. through erosion, pollen, human/animal dander, or is "produced", e.g. through combustion (soot), abrasion (tires, brakes) or the processing of solid materials, e.g. grinding, sawing, drilling.The smaller the dust particles, the easier they are to stir up and the longer they take to settle again. Fine dust with < 10 µm remains available in the respiratory air for a long time and is increasingly absorbed into the respiratory tract. Respirable fine dust can penetrate as far as the pulmonary alveoli.

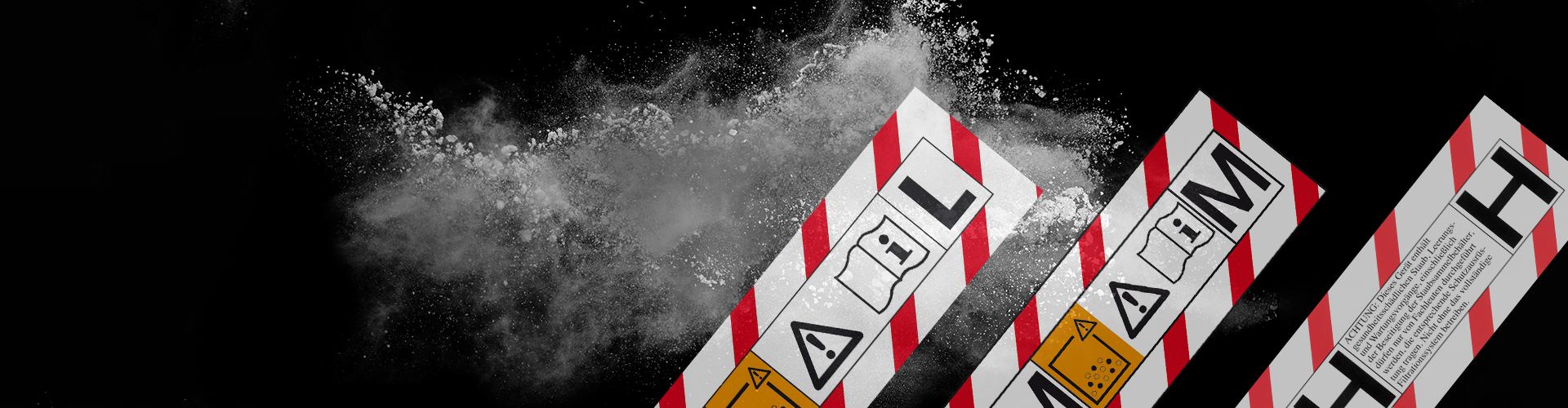

Dust-free instead of construction stop

The new TRGS 504 (Technical Rules for Hazardous Substances) stipulates that in Germany, only dust extractors/vacuum cleaners of dust classes M and H are generally permitted in industry and trade. Since October 2016, inspections have also been carried out on construction sites in Germany. The inspectors are entitled to have the activity stopped if they find a vacuum cleaner that is not permitted. You are on the safe side, for example, with our workshop and construction site vacuum cleaners of the "IPULSE" SERIES.

Dust Classes

The four most important dust classes L, M, H and asbestos briefly explained