starmix manual:

HAZARDOUS SUBSTANCE DUST

1. Dust

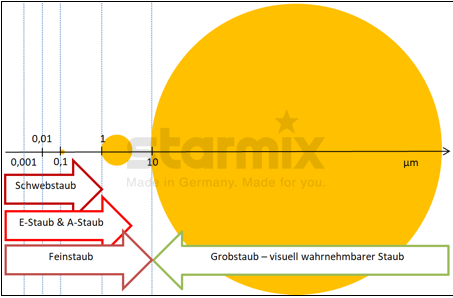

Dust is the collective name for the finest solid particles with a maximum size of 1mm. Dust arises naturally, e.g. from erosion, pollen, human/animal dander or are "produced", e.g. by combustion (soot), by abrasion (tires, brakes) or the processing of solid materials, e.g. grinding, sawing, drilling.

Visually perceptible dust or coarse dust are particles with a size of at least 10µm.

The smaller the dust particles, the easier they are to stir up and the longer they take to settle again. Fine dust with <10µm remains available in the air we breathe for a long time and will be increasingly absorbed into the respiratory tract. Respirable fine dust can penetrate into the alveoli of the lungs.

Suspended dust (smoke) is the dust in the (breathing) air, with a size <1µm. This dust is no longer deposited, but is constantly suspended in the air due to Brownian motion.

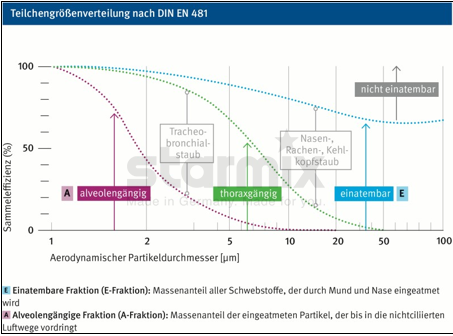

In the Technical Rules for Hazardous Substances, dust is classified according to its inhalability. Dust ≤5µm is called inhalable fraction (E-dust), these particles are so small that they are safely absorbed through the respiratory tract. Alveolar fraction (A-dust) is the fraction of E-dust that can penetrate into the alveoli (alveoli and bronchiole), an exact size cannot be given but only a size distribution depending on the E-dust fraction.

2. Respiratory diseases

The lungs are a natural "high-performance filter" that can cope with a large number of dusts, hazardous substances and pathogens. Coarse dust is not inhaled, but is already separated in the nasal and pharyngeal cavities. Inhalable dust is bound by cilia in the trachea and bronchi and is "coughed up" with mucus or excreted. Alveolar dust can be inhaled into the alveoli (air sacs), where it is surrounded by macrophages (giant phagocytes) and removed.

Like any filtering system, the lungs can become overloaded. The best known of these are asthma, silicosis (dust, stone, coal dust lung) and asbestosis (asbestos dust lung).

The English abbreviation COPD - "chronic obstructive pulmonary disease") and the German abbreviation COB - "chronisch obstruktive Bronchitis" stands for chronic (= slowly developing and not curable), obstructive (= narrowing of the airways) bronchitis (= inflammation of the bronchial tubes). The main causes are frequent inhalation of dusts, gases and aerosols, as well as smoking. The frequent inhalation of pollutants destroys the cilia of the bronchial tubes and thus the filtering and cleansing function of the lungs. Pollutants and germs thus reach the alveoli unhindered and destroy them.

COPD develops slowly. When symptoms (shortness of breath, chronic cough, breathing noises, ...) finally appear, the lung function is already severely impaired. In the advanced stage of the disease, the airways are so narrowed that normal daily life is no longer possible and slow death by suffocation follows.

It is estimated that up to 10% of the population suffers from COPD. Particularly affected are people who are exposed to high levels of dust and smokers.

In numbers, this means that out of a total of 894,000 deaths per year in Germany, approximately 66,000 are fine dust deaths (source: European Enviroment Agency; October 11, 2017 ) and 121,000 are smoker deaths (source: German Cancer Research Center "Tabakatlas Deutschland 2015").

In addition, dusts can pose further health hazards (hazardous substances or biological agents). For example, many substances are considered CMR substances (carcinogenic, mutagenic, reprotoxic = carcinogenic, mutagenic, fertility-endangering), these pollutants can be absorbed not only through the respiratory tract, but also in part through the skin or the digestive system.

3. Technical terms

AGW "Occupational exposure limit value Limit value for the time-weighted average concentration of a substance in the air at the workplace in relation to a given reference period. It indicates the concentration of a substance up to which acute or chronic harmful effects on the health of employees are generally not to be expected. (GefStoffV) (Old designation MAK)

AMR "Occupational Medicine Rules reflect the state of occupational medicine and other established occupational medical findings.

Working substances

Biological agents see Biological agents

ASR "Technical Rules for Workplaces"

specify the requirements of the Workplace Ordinance (ArbStättV).

ATE "acute toxicity estimate"

Acute toxicity estimate: corresponds to the lowest (estimated) dose / proportion at which the respective hazard may occur.

ATEX

Directive (Directive 2014/34/EU) Equipment and protective systems intended for use in potentially explosive atmospheres

BAT "Biological Workplace Tolerance Value"

old designation - new designation: BGW

BG "Employer's Liability Insurance Association"

Institution responsible for statutory accident insurance for companies in the private sector and their employees.

BGW "Biological limit value"

Maximum permissible concentration of a substance in the blood of an employee at which no damage to health is to be expected. (Old designation: BAT - Biological Workplace Tolerance Value)

Biological agents Biological agents:

Microorganisms (e.g. bacteria, fungi and viruses), cell cultures and parasites that can cause infections, allergies or toxic effects in humans.

BioStoffV "Biological Substances Ordinance".

Regulation on safety and health protection during activities involving biological agents; the aim is to protect employees during activities involving biological agents (bio-substances).

CAS "Chemical Abstracts Service"

International designation standard for chemical substances.

CLP Regulation

Regulation

(EC) No. 1272/2008 on classification, labeling and packaging of substances and mixtures.

CMR substance "carcinogenic, mutagenic, toxic for reproduction".

Substances which are carcinogenic, mutagenic or toxic for reproduction. There is no AGW for CMR substances.

Deflagration

Explosion slower than the speed of sound caused by the expanding gases produced during a combustion process.

Detonation

Explosion at supersonic speed coupled with a shock wave / detonation wave.

DGUV "Deutsche Gesetzliche Unfallversicherung" (German Social Accident Insurance) Umbrella organization of the employers' liability insurance associations and accident insurance funds.

DIN "German Institute for Standardization"

German standard for tangible and intangible objects, based on the established findings of science, technology and experience.

ELW "Exposure guidance value"

Measured value for a group of substances for which no hazard is to be expected, can also be specified for substances without an ELV; if the ELV is exceeded, the ELVs of the individual substances must be observed.

Emission

to emit, to send, "to send out". Used here in the sense of the release of pollutants.

EN "European standard"

Standards that specify standards for tangible and intangible objects in the EU.

Endothermic

Energy must be supplied for a reaction to occur.

ERB Exposure-risk relationship

Statistical probability of occurrence of cancer from inhalation exposure during activities involving carcinogenic substances. Acceptance risk (accepted hazard) ≤ 4:10,000; tolerance risk ≤ 4:1,000; intolerable risk > 4:1,000.

Exothermic

Energy is released during a reaction.

Explosion

Sudden release of large amounts of energy, generally in the form of temperature, pressure, and kinetic energy.

Explosion range

is the range of concentration of a flammable substance in the air in which an explosion can occur.

Exposure

Latin for "exposure"; used here in the sense of release of a substance or contact of a substance with the organism.

Flash point

Lowest temperature at which a liquid can form an ignitable vapor-air mixture under normal conditions.

GefStoffV "Ordinance on Hazardous Substances"

Ordinance on protection against hazardous substances; the aim is to protect people and the environment against substance-related damage.

GHS "Globally Harmonized System of Classification, Labelling and Packaging of Chemicals". Internationally valid system for the classification & labeling of chemicals.

IEC "International Electrotechnical Commission"

international standardization organization in the field of electronics and electrical engineering.

IFA "Institute for Occupational Safety and Health"

Research, consulting and testing institute of the DGUV.

Inhalation

Inhalation of solid, liquid or gaseous substances. Here in connection with inhalative hazards, the inhalation of hazardous substances.

Immission

Entry, insertion, received. Used here in the sense of entry of hazardous substances into the white area.

ISO "International Organization for Standardization"

International standardization organization for tangible and intangible objects.

Cavitation

Formation and collapse of vapor bubbles

Contamination

Presence of hazardous substances or biological agents beyond a basic level of contamination that is harmless to health. (Secondary contamination= spreading of contamination to previously uncontaminated areas).

Critical temperature

At which he phase transition (change of aggregate state) of a substance occurs.

LD/LC "Lethal Dose / Lethal Concentration"

Dose or concentration of a substance or radiation that has a lethal effect on certain living beings. An average value of the effect within a population is given (e.g. LD50 rat = lethal dose for 50% of the test animals); in addition, information on the mode of administration or duration of effect may be given.

MAK "Maximum workplace concentration"

Maximum permissible concentration of a substance in the air breathed at the workplace. New designation AGW

Normal conditions

(air) temperature: approx. 20°C and (air) pressure: approx. 101.3 kPa

PPE "Personal Protective Equipment"

Individual equipment to prevent injuries and (health) impairments.

RAB "Rules for occupational health and safety on construction sites"

Concretization of state occupational health and safety regulations for safe and healthy working conditions on construction sites.

REACH "Registration, Evaluation, Authorisation and Restriction of Chemicals"

European Regulation on Registration, Evaluation, Authorisation and Restriction of Chemicals

Black and white separation

Technical and / or organizational demarcation between contaminated and non-contaminated areas.

Substitution

Substitute. Used here in context: to replace a hazardous substance with a non-hazardous one.

TR... "Technical Rule"

Recommendations and technical proposal for complying with laws and regulations, e.g.: TRGS Technical Rule for Hazardous Substances, TRBA Technical Rule for Biological Agents.

VDI guidelines (rules for the "Association of German Engineers")

"Standard for proper technical procedure", procedure recommendation according to the state of the art.

4. Vacuum cleaner

4.1 Basic terms

4.1.1 Negative pressure

Negative pressure ("negative pressure difference") is the difference between ambient pressure and lower pressure in a container. In vacuum cleaners, the negative pressure is created by the permanent transport of air out of the container and the counteraction of the ambient air into the container (pressure compensation = suction effect). This pressure compensation is used to pick up ("lift") vacuumed material.

The heavier the material to be sucked or the greater the difference in height - the higher the vacuum must be.

The higher the vacuum, the more the accessories "suck in" to the vacuum.

Indication in:

Millibar-> Kilo Pascal -> Meter water column

100 mbar = 10 kPa = 1,0197 mWs

Caution: On the one hand, the vacuum gives an indication of the height difference over which the suction material can be picked up (whereby at 100 mbar it is possible to suck from a depth of approximately 1 m) and cannot be increased "to infinity" - the theoretical maximum is 1 bar.

4.1.2 Volume flow - air velocity

Volume flow (also air volume) is the indication of the volume of transported air (in liters, m³, ...) in a period of time (in second, minute, hour). The transported air transports the suction material absorbed by the vacuum.

1 l/s = 60 l/min = 3.6 m³/h

However, the air velocity (in meters per second) is decisive for the transport of the suction material, i.e. the volume flow divided by the (hose) diameter.

Lightweight suction material can be transported in the hose at low air velocity. Heavy suction material (coarse sand, metal dust, etc.) requires high air velocities.

The air velocity can be influenced by the turbine power and / or the selected hose diameter.

Indication in:

Meter/second = m/s

For dust class M or H vacuum cleaners, the minimum air velocity in the suction hose must be at least 20 m/s! If this air velocity is undershot (after the filter), the vacuum cleaner must give an acoustic or visual alarm. If it is possible to connect accessories (suction hoses) with different diameters, a setting option (preselector switch) must be available on the unit to ensure that the warning device responds when the air speed falls below 20 m/s for the respective hose diameter used.

4.2 Drive types

4.2.1 Motor-turbine units

Light AC motors (rarely three-phase motors) that drive a single- or multi-stage turbine to generate the volumetric flow. Several motor-turbines can be installed to increase the volume flow. Vacuum cleaners with motor-turbine units are usually mobile dust collectors (light, mobile vacuum cleaners) with a volume flow of up to approx. 60 - 75 l/s per motor (usually one- to three-motor units).

Carbon brush motors are inexpensive, but generate flying sparks (not suitable for combustible dusts, when used in explosive atmospheres, or in ESD-protected areas) and abrasion (not suitable in clean rooms or hygienic areas). Carbon brush motors have approximately 200-1,000 hours of operation until the carbon brushes wear out (and carbon brushes cannot be replaced on all motors).

Magnetic rotor, EC motors are electronically commutated (brushless) motors (and considerably more expensive than carbon brush motors), here there is no sparking or abrasion. These motors are mostly installed in explosion-proof devices, devices for use in ESD areas or for use in clean rooms. These motors theoretically run without wear.

- Bypass cooling: cooling and working air of the suction are separated, the turbine is cooled by means of ambient air and is independent of the saturation of the filter

- Continuous cooling: the turbine is cooled by means of the cleaned working air of the suction unit, the cooling air is reduced when the filter is saturated!

4.2.2 Side channel compressor

The side channel compressor sucks in the air through a fast rotating impeller, the air is compressed by centrifugal force and the air flow is increased again by the backflow through the side channel. Thus (theoretically) any volume flow and wear-free operation is possible. Due to their size and power consumption (three-phase current), suction units with side channel compressors are larger industrial suction units with volume flow > 80 l/s.

4.2.3 Compressed air driven turbines

The operation of suction turbines via compressed air is also suitable for an almost wear-free drive of the suction unit, as well as for operation in explosion-proof devices. The volume flow is limited by the compressed air provided

4.3 Filter

The terms used here are (partly) not to be understood as technical terms, but only serve to explain the different modes of operation!

4.3.1 Filter material

Depth filter ("saturation filter"): sucked-in dusts shoot into the filter material and are held by the filter material - the filter "saturates".

In practice, each filter is a combination of both, with the "saturation or accumulation" part predominating in each case.

Glass fiber cellulose filters ("paper filters", "glass fiber filters") are predominantly saturation filters - fine dusts are held by the filter / coarse dusts accumulate on the filter surface. Such filters make sense and are used for vacuum cleaners of dust class H (CMR substances, biological agents ...).

PTFE, PET, Teflon, plastic filters... are mainly accumulation filters, only a (smaller) portion of the fine dust shoots into the filter material. Another advantage is the resistance to moisture, the filters can remain in the device when wet vacuuming or be rinsed out (before vacuuming again, the filters should of course be dried!). It makes sense to use them for non-hazardous (dust class L) and hazardous (dust class M) dusts - or as a (cleanable) pre-filter with a main (after) filter of dust class H.

A filter with unlimited service life is not possible even with very effective filter cleaning, therefore filters should be changed at least once a year.

4.3.2 Filter material

Filter cleaning has become a standard feature of most vacuum cleaners in order to increase the service life of the filter and to be able to work as long as possible without interrupting work.

- mechanically by scraping ("raking")

- mechanically by shaking the filter

by the air reversal principle. In this process, a valve is opened by pressing a button (several times) and the incoming ambient air blows the filter free. For this purpose, a vacuum must be created beforehand (e.g. by closing the suction cup, e.g. by keeping the handle tube closed).

- Electromagnetic shaking function which effectively shakes down the main filters either purely on demand by means of differential pressure measurement or when the vacuum falls below a preset vacuum value during the next work break, thus causing the dust to fall back into the container.

| Advantages | Disadvantages |

|

|

- Air reversal principle in which either purely time-controlled (e.g. every 15 sec.) or also demand-controlled a valve is opened so that the incoming ambient air, which wants to compensate for the vacuum in the container, flushes the filter and frees it from dust.

| Advantages | Disadvantages |

|

|

- Compressed air: The filter is cleaned by compressed air, equivalent to air reversal, but with even higher air velocities and pressure differences. The effectiveness of the filter cleaning no longer decreases with the filling level of the container.

4.3.3 Disposable dust collection containers.

Vacuumed dusts should not be poured out or decanted; this is prohibited for dust classes M & H, as well as combustible / explosive dusts. Disposable dust collection containers are used for low dust (ideally dust-free) disposal of vacuumed material.

Filter bags: almost completely closed bag made of paper or non-woven material, through which the suction stream is passed to separate the coarser components of the dust - i.e. more of a coarse dirt filter. A complete filling of the filter bag is not possible (due to technical reasons) - ideally the filling is max. 2/3 of the volume. Removal is possible with little dust! Advantage Disadvantages

| Advantages | Disadvantages |

|

|

Disposal bags, containers...: towards the filter material, open bag or container made of material impermeable to air and dust (mostly PE plastic) - equivalent of a garbage bag when removing the suction material. Depending on the construction of the vacuum cleaner, it is possible to completely fill (possibly even overfill) the disposal bag. Removal is possible with little dust. Advantage Disadvantage

| Advantages | Disadvantages |

|

|

Longopac, EasyPac: Functionality as with the disposal bag / container system, but individual dust-tight packaging units (Longopac) or the complete vacuumed material (EasyPac) can be removed dust-free.

| Advantage | Disadvantage |

| - |

4.4 Difference between dust classes and HEPA filter classes

Dust classes (L; M; H) apply to vacuum cleaners (high particle count, high air velocities, "small" filters)!

Filter classes (EPA; HEPA; ULPA) apply to airborne dusts (low particle count; low air velocities, "large filters")!

A filter can have a test for dust class (according to DIN EN 60335-2-69) and filter class (according to DIN EN 1822) if it has been tested according to both standards. But the installation of a filter tested exclusively for EPA; HEPA or ULPA in a vacuum cleaner does not make it a safety or hazardous material vacuum cleaner.

| Dust class | Suspended matter class | |

| Standard | DIN EN 60335-2-69 | DIN EN 1822 |

| Scope of application | Vacuum cleaners, dust extractors (vacuum holding devices, sweepers) | HEPA and particle filters in the field of room and process air technology |

|

Classes | L - light hazard

| Particle filter (EPA)

High efficiency particulate air (HEPA) filter

High efficiency particulate air filter (ULPA medical technology)

|

| Test | Test filter element: test with oil particles or salt particles (NaCl) with 90% of particle number <2µm Test assembled machine at dust class M & H: test with limestone dust 10% <1µm; 22% <2µm; 75% <5µm. Test bursting strength of filter (filter surface load). "Cushion nails" test | Separation efficiency leakage test for a particle size of 0.3µm to 0.5µm (with liquid or solid test aerosol) |

4.5 Suction cup types

4.5.1 Liquid aspirators

Machines for the exclusive suction of liquids (water, oil...). No filtration of aerosols that may be produced during suction or when vacuuming dry dust.

When selecting the equipment, make sure that it is equipped with a shut-off or closing device when the maximum liquid level is reached, in case of foaming these devices usually do not work (possible option: use defoamers).

The goal is to have a way to drain the unit, such as drain hose, dirty water pump, thrust reverser....

4.5.2 Dry vacuum cleaner

Machines for the exclusive vacuuming of particles. For commercial use, equipment complying with the IEC / DIN EN 60335-2-69 standard must be used. This standard also specifies the requirements for equipment according to dust classes L, M and H.

4.5.3 Wet-dry vacuum cleaners

Machines suitable for vacuuming liquids AND dusts, thus these devices must also meet the requirements for both media!

4.5.4 Vacuum cleaner / industrial vacuum cleaner

Machine for sucking up dusts that have already been deposited. In commercial use, these devices are referred to as "industrial vacuum cleaners" (IS) and must comply with the IEC / DIN EN 60335-2-69 standard.

4.5.5 Dust extractor / EOB

Machines for extracting dust from dust-generating machines. Mobile dust extractors are referred to as "mobile dust extractors" (EOB) and must comply with the IEC / DIN EN 60335-2-69 standard.

4.5.6 Pre-separators

4.5.7 Air cleaners / negative pressure holding devices

Machines used to collect and filter out airborne dust and to clean the air. Air cleaners do not have to be type-tested according to the IEC / DIN EN 60335-2-69 standard, but must comply with DGUV Principle 309-012.

- Main filter made of tested filter material of dust class M or H (H13 or H14 - pay attention to bursting strength!)

- Test of tight installation of the filter and achievement of the filtration degree (DOP-TEST)

- Indication of the shortfall of the minimum air volume

- Indication of the maximum room area that can be exhausted or the air flow rate

are air cleaners which are additionally suitable for ensuring negative pressure in a closed area by extracting air from this area.

4.6 Vacuuming dusts hazardous to health

4.6.1 Dust classes

The worldwide standard IEC 60335-2-69 and its European equivalent DIN EN 60335-2-69 define three dust classes for vacuum cleaners and dust extractors for commercial use.

In addition, the machines must meet additional requirements for vacuuming combustible dusts, operation in explosive atmospheres and with asbestos (according to TRGS 519).

a) Dust class L

(low = slight danger)

Requirements: :

Transmittance < 1% / Separation efficiency >99%.

Filter area load: 500 m³ x m-² x h-1

b) Dust class M

(medium = including hazardous dusts)

For the collection of dusts with an exposure limit value greater than at least 0.1 mg/m³ = dusts hazardous to health (e.g. grinding and sawing dusts of wood, lacquers, cement).

- Transmittance < 0.1% / Separation efficiency >99.9%.

- Filter area load: 200 m³ x m-² x h-1

- Closure option against unintentional release of dust.

c) Dust class H

(high = including carcinogenic dusts and pathogens)

For collection of dusts with all exposure limits, including carcinogenic and pathogenic dusts (e.g. lead, quartz, mold).

- Transmittance < 0.005% / Separation efficiency > 99.995%

- Filter area load: 200 m³ x m-² x h-1

- Closure possibility against unintentional release of dust

- Main filter must only be replaceable with tools

d) Additional requirement for asbestos

Approval of the vacuum cleaner according to dust class H with at least the following additional

requirements::

- Up to 1,200 W main filter dust class H

- From 1,200 W cleanable pre-filter dust class M and main filter dust class H

- From 1,200 W connection for an exhaust hose to the outside (recommended below 1,200 W)

- dimensionally stable dust collection device

Marking: :

- iPulse H-1235 Asbestos Safe Plus

- Dust class M thus also fulfills the requirements of dust class L

- Dust class H thus also fulfills the requirements of dust classes M and L

- Dust class H+Asbestos thus also fulfills the requirements of dust classes H, M and L.

BUT: Simply by installing an M or H filter (e.g. in a dust class L vacuum cleaner), no device fulfills the requirements for the respective higher dust class!

4.6.2 Testing for dust class

Dust extractors and industrial vacuum cleaners must be tested according to the DIN EN 60335-2-69 standard for type or design. This test must be carried out by an independent testing institute (e.g. IFA - Institut für Arbeitsschutz; SLG; TÜV Süd) and verified by a test certificate ( type or design test ).

a) Filter test

- Dust classes L and M: Testing of the filter material with a test dust in a concentration of 200mg/m³ - 90% of the test dust must have a particle diameter between 0.2µm and 2µm.

- Dust class L: filter material permeability < 1%.

- Dust class M: filtration material permeability < 0,1%.

- Dust class H: Testing of the main filter element with a test aerosol (e.g. DOP dispersed oil particles) in a concentration between 10mg/m³ and 200mg/m³ - 90% must have a diameter below 1µm.

- Dust class H: Pass rate of main filter element < 0,005%.

b) Equipment testing

- For dust class M and H, the assembled overall device must be tested (in addition to the filter test).

- Test with limestone dust (particle size distribution: 10% < 1µm, 22% < 2µm, 75% < 5µm) and in a concentration of at least 5g/m³ for falling below the prescribed transmittance (M < 0.1%; H < 0.005%),

- bursting strength of the main filter in case of overfilling and impulse action,

- Filter cleaning must not impair the filtering effect (do not increase the degree of permeability),

- Suction of pad nails, the filter element must not be damaged in the process,

- A filter cleaning must restore the required suction power (min. 20% greater than the minimum air volume),

- The machines must be equipped with an indicator (acoustic or visual) or a shutdown of the connected, dust-generating machine for falling below the minimum air flow rate of 20m/s in the suction hose or pipe (largest diameter that can be used),

- if different diameters require adjustment of the flow rate, this must be possible without tools

- Machines must be equipped with a disposable dust collection container, which enables the suction material to be removed with as little dust as possible.

4.7 Requirements for operation in explosive atmospheres

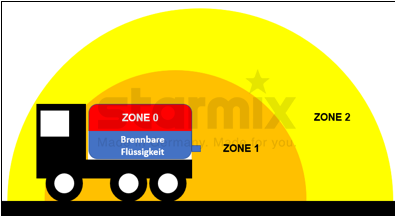

An explosive atmosphere exists if the following conditions are fulfilled simultaneously: combustible or explosive dust, liquid or gas, distributed with sufficient oxygen (air), presence of an ignition source. If one of these conditions does not apply, it can be assumed that there is no explosive atmosphere. Combustible dusts are particles with a size of less than < 1mm that can cause an explosion in air by means of an ignition source. Combustible and explosive dusts are listed in the GESTIS dust explosion database (http://staubex.ifa.dguv.de) and classified in explosivity/dust explosion class:

| Dust explosion class | KST in bar x m x m/s |

| St 1 | 0 to 200 bar x m x m-1 |

| St 2 | 200 to 300 bar x m x m-1 |

| St 3 | 300 to x m x m-1 |

Suction units operated in areas with explosive atmospheres or used to suck up combustible dusts must comply with the requirements of ATEX Product Directive 2014/34/EU. If equipment is operated in areas with explosive atmospheres, only suitable machines may be used. The requirements are specified in the ATEX Directive (Directive 2014/34/EU). Minimum requirements for the protection of employees who may be endangered by explosive atmospheres are laid down in the ATEX Operational Directive (Directive 1999/92/EC), implemented by the Operational Safety Ordinance (BetrSichV). Equipment and protective systems must comply with the ATEX Product Directive (Directive 74/9/EC). Implemented for Germany by the "Eleventh Ordinance to the Product Safety Act" (Explosion Protection Products Ordinance - 11th ProdSV).

4.7.1 Classification into equipment groups

Equipment Group I:

Equipment for use in mines - underground operations, and their surface installations, which may be endangered by mine gas and / or combustible dusts.

| Category | |

| M1 | Very high safety Safety must be ensured in the event of the occurrence of two simultaneous, independent faults. |

| M2 | High safety Shutdown in case of explosive atmosphere |

Equipment Group II:

Equipment for use in all other areas that may be endangered by explosive dust or gas atmospheres.

| Category | ATEX-Zone | Safety |

| 1 | Zone 0 / 20 | Very high safety Safety must be ensured in the event of the occurrence of two simultaneous, independent faults. |

| 2 | Zone 1 / 21 | High safety Safety must be ensured in the event of the occurrence of one fault. |

| 3 | Zone 2 / 22 | Normal safety |

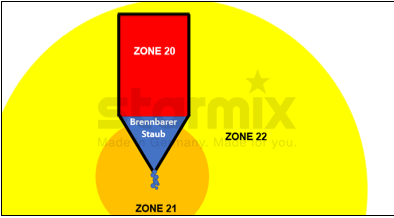

4.7.2 Classification of ATEX zones

Explosive areas are areas in which an explosive atmosphere is present. The employer must assign these areas to zones (risk assessment):

| Substance group | ATEX zone | Explosion hazard |

| 0 | continuously, frequently, over a longer period of time | |

| Gas (G) Vapor; aerosol; mist | 1 | occasionally (during normal operation) |

| 2 | rarely or for a short time |

| 20 | Constantly, frequently, over a long period of time | |

| Dust (D) | 21 | occasionally (during normal operation) |

| 22 | rarely or for a short time |

Liquids with a flash point <55°C are considered as flammable gas (DIN EN 60335-2-69 Pkt.1). If flammable aerosols are formed, these are also considered to be a gas.

Basic safety requirements:

- Primary explosion protection: avoidance or restriction of the formation of explosive atmospheres (ventilation; inerting; substitution ...)

- Secondary explosion protection: avoidance of ignition sources (use of equipment in accordance with ATEX equipment groups; ...)

- Tertiary explosion protection: limitation of the effects of a possible explosion (constructive explosion protection).

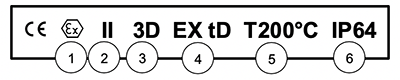

4.7.3 Marking of explosion-protected equipment

Each device must be clearly marked with information on the manufacturer / trade name / brand, device designation, CE marking. In addition, the exact marking for use:

1. each device must be marked with the explosion protection mark:

2. equipment group

| I | mining |

| II | all other areas |

| 1G | ATEX Zone 0 |

| 2G | ATEX Zone 1 |

| 3G | ATEX Zone 2 |

Dust:

| 1D | ATEX Zone 20 |

| 2D | ATEX Zone 21 |

| 3D | ATEX Zone 22 |

4. explosion protection "Ex":

| i | intrinsic safety (ia for Zone 0; ib for Zone 1 & 2). |

| d | flameproof enclosure |

| e | increased safety |

| p | pressurized enclosure |

| o | oil encapsulation |

| m | encapsulation |

| q | sand encapsulation2 |

| n | type of protection zone 2 (nA non-sparking; nC protected contacts; nR vapor-proof enclosure; nL energy-limited; nP simplified pressurized enclosure) |

| s | special protection |

| pD | pressurized enclosure |

| iD | Intrinsic safety |

| mD | Encapsulation |

| tD | Protection by housing |

5. temperature class or surface temperature

| T1 | Temperature class ≤ 450°C |

| T2 |

Temperature class |

| T3 |

Temperature class |

| T4 |

Temperature class |

| T5 |

Temperature class |

| T6 |

Temperature class |

| ...°C | Surface temperature |

6. protection class according to IP (suitability of electrical equipment against potential hazards according to DIN EN 6029).

First code number: Protection against foreign bodies

| 0 | no protection |

| 1 | Protection against foreign bodies ≥50mm |

| 2 | Protection against foreign bodies ≥12,5mm |

| 3 | Protection against foreign bodies ≥2,5mm |

| 4 | Protection against foreign bodies ≥1mm |

| 5 | protection against dust |

| 6 | dust-tight |

Second digit: Protection against water

| 0 | no protection |

| 1 | Protection against dripping water |

| 2 | protection against dripping water from angle of housing up to 15 |

| 3 | Protection against falling spray water from angle up to 60°. |

| 4 | Protection against splashing water from all sides |

| 5 | Protection against water jets |

| 6 | Protection against strong jets of water |

| 7 | Protection against temporary immersion |

| 8 | Protection against permanent immersion |

If a code number cannot be specified, it is replaced by an "X" (e.g. IP X4).

4.7.3 Marking of explosion-proof devices

4.8 ESD Vacuum cleaner

No electrostatic discharges may occur in ESD protected areas!

Suction devices for use in ESD protected areas must meet the following requirements (DIN EN 60335-2-69 Annex DD):

- Leakage resistance of entire device ≤ 1MΩ

- No generation of electrostatic charge

- Dust class L, M or H

- Protection class 1

- At least protection class IP 54

- Accessories electrostatic dissipative

Marking:

4.9 Cleanroom vacuum cleaners

Relevant standards for cleanrooms only specify the requirements for the maximum number of particles as a function of the particle size in the cleanrooms.

Relevant standards are ISO 14644 (semiconductor technology, aerospace); VDI 2083 (food); EU-GMP Guideline Annex 1 (pharmaceuticals).

There is no (testing or certification) standard on cleanroom vacuums and the requirements can only be derived based on the cleanroom classes.

Since every particle must be avoided in all cleanrooms, the vacuums should:

- have the highest separation rate (dust class H),

- not generate any additional dust (carbon brushless motors = magnetic rotors, EC motors; abrasion-resistant surfaces, especially on the wheels)

- do not generate electrostatic charges (e.g. ESD or ATEX vacuums).

5. health hazards

5.1 Intake routes

Substances can enter our bodies in various ways:

| Resorptive | Absorption via skin and mucous membranes. |

| Inhalation | Absorption via the respiratory tract |

| Dermal | Absorption via skin |

| Oral | uptake by swallowing |

The route of absorption may depend on whether the substance is present as a particle, liquid, gas, vapor or aerosol. According to the CLP Regulation (Regulation (EC) No. 1272/2008), substances must be evaluated and classified according to their hazards.

5.1.1 Resorptive

Resorptive is absorption via skin (dermal) and mucous membranes. Since mucous membranes are located in the respiratory and digestive areas, this always includes inhalation and oral uptake.

5.1.2 Inhalation

This does not work with fibers classified as carcinogenic (WHO fibers), because the scavenger cells cannot completely surround them and they die in the process. If these fibers are non-biodegradable, these fibers can be destroyed and shedding can occur. Biobiodegradable fibers are not destroyed or are destroyed only very slowly and remain in the body for a correspondingly long time!

Respirable fibers with certain characteristics are classified as carcinogenic, carcinogenic fibers (WHO fiber):

- Length > 5µm

- diameter < 3µm

- Length-to-diameter ratio > 3:1

- (Biostability)

Biostability determines the residence time in body tissue. For safety, a maximum permissible half-life of 40 days is specified, i.e. to exclude a cancer hazard, half of the fibers must have dissolved after 40 days.

5.1.3 Dermal

5.1.4 Oral

Ingestion by swallowing. Substances that are harmful to health through the digestive system, for this these substances must be swallowed.

5.2 Classification and labeling according to CLP regulation (GHS)

According to the CLP Regulation (Regulation (EC) No. 1272/2008), substances must be evaluated, classified and labeled according to their hazards. For this purpose, the manufacturer or distributor must provide a safety data sheet.

Safety data sheet, mandatory information:

- Name of the substance or mixture and of the company.

- Possible hazards

- Composition/information on ingredients

- First aid measures

- Fire fighting measures

- Maßnahmen bei unbeabsichtigter Freisetzung

- Accidental release measures

- Handling and storage

- Exposure controls / Personal protective equipment

- Physical and chemical properties

- Stability and reactivity

- Toxicological information

- Environmental information

- Disposal information

- Transport information

- Regulatory information

- Other information

(Sample safety data sheets can be found at www.baua.de).

5.2.1 Biological health hazards

a) Acute toxicity

Harmful effects that occur when a substance or mixture is administered orally or dermally in a single dose or in multiple doses within 24 hours or inhaled for 4 hours. The classification of acute toxicity refers to the individual substances; in the case of mixtures, the acute toxicity is to be calculated on the basis of the individual substances (on the basis of the ATE values). This may result in a completely new hazard category.

| Classification | Hazard statement |

| Category 1 / Acute Tox 1 | H300 - Fatal if swallowed. H310 - Danger to life by skin contact. H330 - Danger to life by inhalation |

| Category 2 / Acute Tox 2 | H300 - Danger to life if swallowed. H310 - Danger to life by skin contact. H330 - Danger to life by inhalation. |

| Category 3 / Acute Tox 3 | H301 - Toxic if swallowed. H311 - Toxic in contact with skin. H331 - Toxic by inhalation. |

| Classification | Hazard statement |

| Category 4 / Acute Tox 4 | H302 - Harmful if swallowed.

H312 - Harmful in contact with skin. H332 - Harmful by inhalation. |

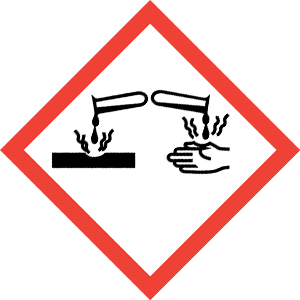

b) Corrosive / Irritant effect on skin

Corrosivity is irreversible (incurable) skin damage within an observation period of 14 days, e.g. burns, necrosis, ulcers, bleeding, etc.

Irritant effect a reversible (curable) skin damage, e.g. redness, scabbing, inflammation ... (which may also lead to irreversible skin damage with repeated exposure).

Labeling:

| Classification | Hazard statement |

| Category 1A / Skin Corr. 1A Category 1B / Skin Corr. 1B Category 1C / Skin Corr. 1C | H314 - Causes severe skin burns and eye damage. |

| Classification | Hazard statement |

| Category 2 / Skin Irrit. 2 | H315 - Causes skin irritation |

c) Serious eye damage / eye irritation

| Classification | Hazard statement |

| Category 1 / Eye Dam. 1 | H318 - Causes severe eye damage |

| Classification | Hazard statement |

| Kategorie 2 / Eye Irrit. 2 | H319 - Causes severe eye damage |

| Classification | Hazard statement |

| Category 1A / Resp.Sens. 1A | H334 - May cause allergy, asthma-like symptoms or breathing difficulties if inhaled. |

| Category 1B / Resp. Sens. 1B |

H334 - May cause allergy, asthma-like symptoms or breathing difficulties if inhaled. |

|

Category 1 / Resp. Sens. 1 |

H334 -May cause allergy, asthma-like symptoms or breathing difficulties if inhaled. |

Labeling:

| Classification | Hazard statement |

| Category 1A / Skin Sens. 1A | H317 - Causes severe eye irritation |

|

Category 1B / Skin Sens. 1B |

H317 - Causes severe eye irritation |

|

Category 1 / Skin Sens. 1 |

H317 - Causes severe eye irritation

|

| Classification | Hazard statement |

| Category 1A / Muta. 1A | H340 - May cause genetic defects (specify route of exposure if there is conclusive evidence that no other route of exposure presents this hazard). |

|

Category 1B / Muta. 1B |

H340 - May cause genetic defects (specify route of exposure if there is conclusive evidence that no other route of exposure presents this hazard). |

Labeling:

| Classification | Hazard statement |

| Category / Muta. 2 | H341 - Suspected of causing genetic defects. (Specify route of exposure if there is conclusive evidence that no other route of exposure presents this hazard). |

f) Carcinogenic effect

| Classification | Hazard statement |

| Category 1A / Carc.. 1A | H350 - May cause cancer. (Specify route of exposure if there is conclusive evidence that no other route of exposure presents this hazard). |

|

Category 1B / Carc. 1B |

H350 - May cause cancer. (Specify route of exposure if there is conclusive evidence that no other route of exposure presents this hazard). |

Labeling:

| Classification | Hazard statement |

| Category 2 / Carc.. 2 | H351 -Suspected of being carcinogenic. (Specify route of exposure if there is conclusive evidence that no other route of exposure presents this hazard). |

For carcinogenic substances of category 1 there is no concentration threshold or occupational exposure limit (OEL) at which a carcinogenic effect can be excluded. An exposure-risk relationship (ERB) is specified for the substances, up to which concentration a statistical probability of the occurrence of a cancerous disease is accepted or tolerated (TRGS 910):

- Acceptance risk: 4 : 10,000 (target: 4 : 100,000)

- Tolerance risk: 4 : 1,000

- Exceeding the tolerance risk is equivalent to a "non-tolerable risk.

Labeling:

| Classification | Hazard statement |

| Category 1A / Repr. 1A | H360 - May impair fertility or harm the unborn child. (specify specific effect if known) (specify route of exposure if it is conclusively demonstrated that there is no hazard from any other route of exposure). |

|

Category 1B / Repr. 1B |

H360 - May impair fertility or harm the unborn child. (specify specific effect if known) (specify route of exposure if it is conclusively demonstrated that there is no hazard from any other route of exposure). |

Labeling:

| Classification | Hazard statement |

| Category 2 / Repr.. 2 | H361 - Suspected of damaging fertility or harming the unborn child. (if known, specify specific effect) (specify route of exposure if it is conclusively demonstrated that there is no hazard from any other route of exposure). |

| Classification | hazard statement |

| Lact. | H362 - May cause harm to infants through breast milk |

h) Specific target organ toxicity

| Classification | Hazard statement |

| Category 1 / STOT SE 1 | H370 - Causes damage to organs (or list all organs affected if known) (specify route of exposure if it is conclusively demonstrated that no other route of exposure presents this hazard) |

Labeling:

| Classification | Hazard statement |

| Category 2 / STOT SE 2 | H371 - May cause damage to organs (or list all organs affected if known) (specify route of exposure if it is conclusively demonstrated that no other route of exposure presents this hazard) |

Labeling:

| Classification | Hazard statement |

| Category 3 / STOT SE 3 | H335 - May cause respiratory irritation. H336 - May cause drowsiness and dizziness. |

Labeling:

| Classification | Hazard statement |

| Category 1 / STOT RE 1 | H372 - Causes damage to organs through prolonged or repeated exposure (or list all organs affected if known) (specify route of exposure if it is conclusively demonstrated that no other route of exposure presents this hazard) |

Labeling:

| Classification | Hazard statement |

| Category 2 / STOT RE 2 | H373 - May cause damage to organs through prolonged or repeated exposure (or list all organs affected if known) (specify route of exposure if it is conclusively demonstrated that no other route of exposure presents this hazard) |

i) Aspiration hazard

| Classification | Hazard statement |

| Category 1 / Asp. Tox. 1 | H304 - May be fatal if swallowed and enters airways |

- Risk group 1: Biological substances that are unlikely to cause disease in humans (e.g. almost all molds)

- Risk group 2: Biological agents that may cause disease in humans and could pose a hazard to employees; unlikely to spread to the general population; effective prevention or treatment is usually possible (e.g., Aspergillus fumigatus; hepatitis A)

- Risk Group 3: Biological agents that may cause serious disease in humans and pose a serious hazard to workers; risk of spread in the population may exist, but effective prevention or treatment is usually possible (e.g., hepatitis B)

- Risk group 4: Biological agents that cause serious disease in humans and pose a serious hazard to workers; the risk of spread in the population may be high ; usually effective prevention or treatment is not possible (e.g. Ebola, Lassa fever).

- Amiodarone

- Benzophenone

- Fluoroquinolones

- Furanocoumarins

- Hypericin

- Isotretinoin

- Naproxen

- Porphyrins

- Sulfonamides

- Tetracyclines

5.2.2 Physical hazards

a) Physical properties of substances and mixtures

Ignition temperature: Minimum temperature at which a flammable substance self-ignites in air, given in degrees Celsius (°C) or Kelvin (K).

pyrotechnic articles ("explosives for entertainment purposes")

unstable substances and mixtures ("explosives too sensitive for normal handling ").

Labeling:

| Classification | Hazard statement |

| unstable explosive / Unst. Expl. | H200 - unstable, explosive |

| Division1.1 / Expl. 1.1 | H201 - Explosive; danger of mass explosion. |

| Division1.2 / Expl. 1.2 | H202 - Explosive; great danger from fragments, explosives and thrown objects. |

| Division1.3 / Expl. 1.3 | H203 - Explosive; danger from fire, air pressure or fragments, explosive and thrown objects. |

| Division1.5 / Expl. 1.5 | H205 - Danger of mass explosion in case of fire. |

| Classification | Hazard statement |

| Division1.4 / Expl. 1.4 | H204 - Danger from fire or splinters, explosives and thrown objects. |

|

Classification |

Hazard statement |

| Division 1.6 / Expl. 1.6 | No hazard warning |

| Classification | hazard statement |

| Category 1 / Flam. Gas 1 | H220 - Extremely flammable gas. |

|

Classification | Hazard statement |

| Subclass 2 / Flam. Gas 2 | Flammable gases. |

- non-refillable containers filled with gas (compressed, liquefied or under pressure), liquids and/or solids (as paste or powder)

- possibility of removal of the contents as foam, paste, powder in liquid or gaseous form.

| Classification | Hazard statement |

| Category 1 / Aerosol 1 | H 222 - Extremely flammable aerosol |

| Classification | Hazard statement |

| Category2 / Aerosol 2 | H223 - flammable aerosol |

| Classification | Hazard statement |

| Category 1 / Ox. Gas 1 | H270 - May cause or intensify fire; oxidizer |

| Classification | Hazard statement |

| compressed gas / Comp. | H280 - Contains gas under pressure; may explode if heated. |

| Liquefied gas / Liq | H280 - Contains gas under pressure; may explode if heated. |

| Refrigerated liquefied gas / Ref. Liq | H281 - Contains refrigerated gas; may cause cold burns or injury. |

| Dissolved gas / Diss. | H280 - Contains gas under pressure; may explode if heated. |

| Classification | Hazard statement |

| Category 1 / Flam. Liq. 1 | H224 - Extremely flammable liquid and vapor. |

|

Category | H225 - Highly flammable liquid and vapor. |

|

Category | H226 - Flammable liquid and vapor. |

| Classification | Hazard statement |

| category 1 / Flam. Sol. 1 | H228 - Flammable solid |

|

category | H228 - Flammable solid |

| Classification | Hazard statement |

| Typ A / Self-react. A | H240 - Heating can cause explosion |

| Classification | Hazard statement |

| Typ B / Self-react. B | H241 - Heating can cause fire or explosion |

| Classification | Hazard statement |

| Typ C / Self-react. C | H242 - Heating can cause fire |

| Typ D / Self-react. D | H242 - Heating can cause fire |

| Classification | Hazard statement |

| Typ E / Self-react. E | H240 - Heating may cause explosion |

| Typ F / Self-react. F | H242 - Heating may cause fire |

|

Classification |

Hazard statement |

| Typ G / Self-React. G | no hazard warning |

| Classification | hazard warning |

| Category 1 / Flam. Gas 1 | H230 -Can react explosively even in the absence of air |

| Category 2 / Flam Gas 2 | H231 – May also react explosively in the absence of air at elevated pressure and/or temperature. |

| Classification | Hazard warning |

| Liquid Category 1 / Pyr. Liq. 1 | H250 -Self-ignites in contact with air. |

| Solid Category 1 / Pyr. Sol. 1 | H250 - Self-ignites in contact with air |

| Classification | Labeling | Hazard statement |

| Category 1 / Self-Heat 1 | Danger | H251 - Self-heating, may catch fire |

| Category 2 / Self-Heat. 2 | Warning | H252 - Self-heating in large quantities, may catch fire. |

| Classification | Labeling | Hazard statement |

| Category 1 / Water-react. 1 | Danger | H260 -Contact with water liberates flammable gases which may ignite spontaneously. |

|

Category |

Danger | H260 - Contact with water liberates flammable gases which may ignite spontaneously. |

|

Category | Attention | H261 - Contact with water liberates flammable gases. |

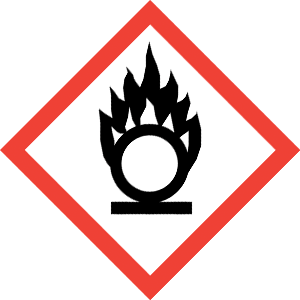

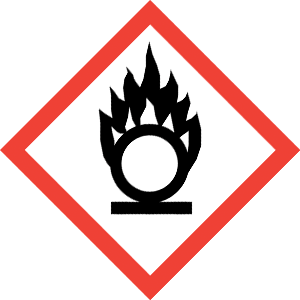

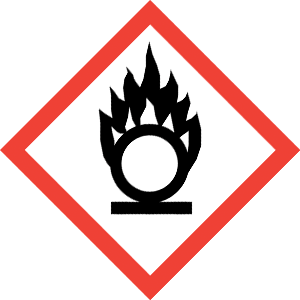

| Classification | Label | Hazard statement |

| Liquid Category 1 / Ox. Liq. 1 | Danger | H271 - May cause fire or explosion; strong oxidizer. |

| Liquid Category 2 / Ox. Liq. 2 |

Danger | H271 - May cause fire or explosion; strong oxidizer. |

| Liquid Category 3 / Ox. Liq. 3 |

Warning | H272 - May intensify fire; oxidizer. |

| Solid Category 1 / Ox. Sol. 1 |

Danger | H271 - May cause fire or explosion; strong oxidizer. |

|

Solid Category |

Danger | H271 - May cause fire or explosion; strong oxidizer. |

|

Solid Category | Warning | H272 - May intensify fire; oxidizer. |

| Classification | Label | Hazard statement |

| Typ A / Org. Perox. A | Danger | H240 - Heating can cause explosion |

| Classification | Labeling | Hazard statement |

| Typ B / Org. Perox. B | Danger | H241 - Heating can cause fire or explosion |

| Classification | Labeling | Hazard statement |

| Typ C / Org. Perox. C | Danger | H242 - Heating can cause fire or explosion |

| Classification | Labeling | Hazard statement |

| Typ E / Org. Perox. E | Attention | H242 - Heating can cause fire |

| Typ F / Org. Perox. F | Attention | H242 - Heating can cause fire |

|

Classification |

Labeling |

Hazard statement |

| Typ G / Org. Perox. G | No symbol | No hazard warning |

| Classification | Hazard warning |

| Category 1 / Met. Corr 1 | H290 - May be corrosive to metals. |

5.2.3 Environmental hazards

| Classification | Labeling | Hazard statement |

| Category 1 / Aquatic Acute 1 | Attention | H400 - Very toxic to aquatic organisms |

|

Classification |

Labeling |

Hazard statement |

| Category 1 / Aquatic Chronic 1 | Attention | H410 - Very toxic to aquatic life with long lasting effects. |

| Category 2 / Aquatic Chronic 2 | Attention | H411 - Toxic to aquatic organisms, with long lasting effects. |

| Classification | Labeling | Hazard statement |

| Category 3 / Aquatic Chronic 3 | no symbol | H412 - Harmful to aquatic organisms, with long lasting effects. |

| Category 4 / Aquatic Chronic 4 | no symbol | H413 - May be harmful to aquatic life with long lasting effects. |

6 Typical pollutants

6.1 A- and E-dust

- At least dust class M

- iPulse M-1635 Safe

- iPulse M-1635 Safe Plus

- ISC M-1625 Safe

- E-dust (inhalable): All dusts that can be inhaled

- A-dust (alveolar): Portion of E-dust that can reach the alveoli (air sacs in the lungs) and bronchioles

- Use of dust-generating materials

- Use of dust-generating machines

- Whirling up of deposited dusts...

- Inhalation

- (depending on the substance, other routes of absorption may be added).

- Asthma

- Chronic bronchitis (COPD)

- Silicosis ("stone or dust lung")

- Activities involving quartz dusts are considered carcinogenic activities

- E-dust: 10 mg/m³

- A-dust: 1.25 mg/m³

- TRGS 504: Activities with exposure to A- and E-dust

6.2 Asbestos

Vacuum cleaner

- Dust class H with additional requirement asbestos

Description

- Naturally occurring silicates with fibrous structure

- Respirable, carcinogenic fibers (L >5mµ; D <3µm; L:D >3:1)

- Amphibole asbestos:

- Amosite - Brown asbestos

- Crocidolite - blue asbestos (spray asbestos).

- actinolite; antophyllite; tremolite

- Serbentine asbestos:

- Chrysotile - white asbestos (accounts for >90% of asbestos used).

- Properties:

- Heat resistant

- Acid and alkali resistant

- Insulating (temperature, electrical)

- Good workability

Occurrence

- Building products:asbestos cement (plates, pipes, fittings, ...); plasters, fillers, adhesives, paints, flooring ...

- Heat or fire protection: sprayed asbestos; fire dampers, fire doors, fire seals, spark arrestors, insulators ...

- Sealants: Sealants, mastics, waterproofing membranes (PAH) ...

- Textiles: heat protection linings, cords, tamping compounds ...

- Friction and clutch facings: in vehicles, elevators, machinery ...

- (over 3,000 known uses of asbestos in products).

Health hazards

Ingestion:

- Inhalation

Health effects:

- Asbestosis (asbestos pneumoconiosis)

- Carcinogen Category 1A / Carc. 1A (lung, larynx. ovarian cancer ; mesothelioma).

„Limits“:

- White range: 1.000 F/m³

- Acceptance concentration: 10.000 F/m³

- Tolerance risk: 100.000 F/m³

Rules, guidelines, leaflets, implementation aids

- TRGS 519: Demolition, renovation or maintenance work

- TRGS 517: Activities involving mineral raw materials potentially containing asbestos and mixtures and products made from them

- Asbestos guideline; guideline for the assessment and remediation of weakly bound asbestos products in buildings

- DGUV Information 201-012 (previously: BGI 664); 201-012 Procedures with low exposure to asbestos during demolition, renovation and maintenance work

- LAGA Merkblatt 23; enforcement aid for the disposal of waste containing asbestos.

Prohibitions:

- 1995 Germany: ban on manufacture, use and placing on the market.

- 2005 EU: ban on manufacture, use and placing on the market

- (with the exception of demolition, renovation and maintenance work (ASI work))

Requirements for ASI work involving asbestos:

- Building owner / client: duty to investigate for asbestos-containing materials (LBO; KrWG).

- Performing companies:

- Expertise according to TRGS 519 for responsible and supervising person

- Approval as a specialist company for AS work on weakly bound asbestos

- Notification of work to the occupational health and safety authority (notification to the employers' liability insurance association)

6.3 Wood dust

Vacuum cleaner

- Up to 1,200 W power consumption and up to 50 liters dust collection container

At least dust class M

- Over 1,200 W power consumption or over 50 liters dust collection container

Additional type 22

Discription

- Wood dust is generated during the machining or processing of wood materials.

- Hardwood dusts are considered carcinogenic!

- Some types of wood are considered sensitizing!

Health hazards

Intake routes:

- Inhalation

Health hazards:

- Asthma

- Chronic bronchitis (COPD)

- Partial carcinogen (hardwood dusts)

- Partially sensitizing

Physical Hazards:

- Flammable solids

Occupational exposure limit (OEL):

- 2 mg/m³ for wood dusts < 100µm

Carcinogenic hardwood dusts according to TRGS 906:

| African Mahagony (KHXX) | Limba (TMSP) |

| Afrormosioa (PKEL) | Lime(TIXX) |

| Maple (ACXX) | Mansonia (MAXX) |

| Balsa (OHXX) | Meranti (SHXX) |

| Birch(BEXX) | Nyaoth |

| Brazilian Rosewood (DLNG) | Obeche |

| Beech (FAXX) | Rosewood(DLXX) |

| Ebony(DSXX) | Poplar(POXX) |

| Oak (QCXX) | Sycamore (PLXX) |

| Alder (ALXX) | Rimu, Red Pine |

| Esche (FXXX) | Teak (TEGR) |

| Hickory (CAXX) | Elm (ULXX) |

| Iroko | Walnut(JGXX) |

| Chestnut (CTXX) | Willow (SAXX) |

| Cowry Pine |

Hornbeam |

| Cherry (FAXX) |

Sensitizing dusts according to TRGS 907:

| Tropische Akazie | African mahogany (KHXX) |

| Coccus wood | Santos rosewood (MHSC) |

| Iroko, Kambala | Bété (MAAL) |

| East Indian rosewood (DLLT) | Peroba do campo (PAPR) |

| African grenadilla wood (DLML) | Peroba jaune |

| Rio rosewood(DLNG) | Teak (TEGR) |

| Cocobolo (DLRT) | Limba (TMSP) |

| Honduras rosewood(DLST) | red cedar, giant live tree |

| Ayan, Movingui (DTBN) | Abachi, Obeche (TRSC) |

| Australian silver areas |

Rules, guidelines, leaflets, implementation aids

- TRGS 553; Wood dust

- DGUV Information 209-044; Wood dust

6.4 Wood preservative

Vacuum cleaner

- Cust class H

- iPulse H-1635 Safe Plus

Description

- Load-bearing wooden structures had to be treated with a preventive wood preservative against fungal attack (fungicide) and insects (insecticide).

Occurrence

- Solvent-based wood preservatives

- DDT - Dichlordiphenyltrichlorethan

- Lindan - gamma-Hexachlorcyclohexan

- PCP - Pentachlorphenol

- (Coal) tar-containing wood preservatives (containing PAHs)

- Coal tar

- Tar oils (coal tar oil, mineral oil and mixtures of both)

- Water-soluble wood preservatives

- Mercury, arsenic, boron, chromium, fluoride, copper, zinc salts.

- Trade names:

- Aroclor (PCB)

- Carbolineen / Karbolineum (Steinkohleteer)

- Clophen (PCB)

- Hylotox 59 (DDT & Lindan; DDR)

- Xylamon (PCP & Lindan, bis 1978, BRD)

- Xyladecor (PCP & Lindan, bis 1978, BRD)

Health hazards

Ingestion

- Resorptive (route of absorption depends on individual substances).

Health effects:

- "wood preservative syndrome", chronic fatigue and exhaustion state.

- Acute toxicity (e.g. DDT - dermal: Cat. 3; oral: Cat. 3; lindane - inhalation: Cat. 4; dermal: Cat. 4; oral: Cat. 3; PCP - inhalation: Cat. 2; dermal: Cat. 3)

- Skin corrosion / irritation (e.g. PCP - Cat. 2)

- Eye irritation (e.g. PCP - Cat. 2)

- Germ cell mutagen (e.g. PCP - Cat. 2)

- Carcinogenic (e.g. DDT- Cat. 2; PCP - Cat. 2)

- Bioaccumulative (e.g. DDT).

Limit values:

- DDT: MAK 1 mg/m³

- Lindan: MAK 0,1 mg/m³

- PCP: MAK 0,1 mg/m³

Rules, guidelines, leaflets, implementation aids

- TRGS 524: Contaminated areas

- DGUV Rule 101-004 (formerly BGR 128): Working in contaminated areas

- PCP Guideline: Guideline for the assessment and remediation of pentachlorophenol (PCP)-contaminated building materials and components in buildings

- (withdrawn: LaGetSi HSM - Handlungsanleitung).

Prohibitions:

- DDT: 1972 application ban BRD (until min. 1990 use in the GDR).

- Lindane: 2008 ban on production, marketing and use EU

- PCP: 1989 ban on manufacture, placing on the market and use in Germany

Requirements for work on wood preservatives:

- Building owner / client: duty to investigate (LBO; KrWG).

- Executing companies:

- Expertise for work in contaminated areas / building pollutants according to DGUV 101-004 6B and TRGS 524 2B for management and supervision

- Notification of the work to the employers' liability insurance association

6.5 KMF - Artificial Mineral Fibers

Vacuum cleaner

- At least dust class M

- iPulse M-1635 Safe

- iPulse M-1635 Safe Plus

- ISC M-1625 Safe

Description

- Man-made glass, stone fibers (ceramic and slag fibers)

- Respirable, carcinogenic fibers (L >5mµ; D <3µm; L:D >3:1)

Occurrence

- Thermal and sound insulation: interior walls/lightweight walls, acoustic ceilings, floors, roof finishing, exterior facades, impact sound insulation, plasters containing mineral fibers, thermal insulation ...

- Fire protection: facade construction, spray insulation, ...

- Building products: KMF panels, suspended ceilings, fiber composites ...

- Horticulture: earth replacement

- …

Health hazards

Intake

- Inhalation

Health effects:

- „Pseudoasbestose“

- Carcinogenic

- Old mineral wool: Cat. 1B

- New mineral wool: Cat. 2

- Irritant effect on the skin

- Eye irritation

"Limit values" old mineral wool:

- Exposure category 1 ≤ 50.000 F/m³

- Exposure category 2 > 50.000 bis ≤ 250.000 F/m³

- Exposure category 3 > 250.000 F/m³

Rules, guidelines, leaflets, implementation aids

- TRGS 521; Demolition, renovation and maintenance work with old mineral wool

- DGUV Information 213-031; Handling of mineral wool insulating materials (glass wool, rock wool)

Prohibitions:

- Old mineral wool: since June 2000 ban on manufacture & use in Germany.

Requirements when working with old mineral wool:

- Building owner / client: duty to investigate (LBO; KrWG).

- Executing companies: Specialized knowledge according to GefStoffV and TRGS 521 for ASI work on old mineral wool

6.6 PAH - Polycyclic aromatic hydrocarbons

Vacuum cleaner

- Dust class H

- (Possibly additionally type 22)

Description

- Group of substances consisting of several hundred individual hydrocarbon compounds (Cn1Hn2; 10≤n1≤96; 8≤n2≤30), Examples: Naphthalene; benz(a)anthracene; acenaphtylene; chrysene; acenaphthene; benzo(b)fluoranthene; fluorene; benzo(k)fluoranthene; phenanthrene; benzo(a)pyrene (BaP); anthracene; dibenzo(a,h)-anthracene; fluoranthene; benzo(g,h,i)perylene; pyrene; indeno(1,2,3-c,d)pyrene; benz(a)anthracene.

- Formed by incomplete combustion (pyrolysis).

- From gaseous (2-3 benzene rings) to solid particles (4 benzene rings or more)

Occurrence

- Tar products: Flooring (mastic asphalt, asphalt tiles); blacktop (asphalt); insulation (tar cork); structural waterproofing (blacktop, horizontal barriers, sealants and roofing membranes)

- Floor adhesives (CAUTION: some contain asbestos)

- Wood preservatives (tar oil, carbolineum)

- Joint sealing compounds

- Filling compounds

- …

Health hazards

Absorption

- Resorptive

Health effects:

- (depending on individual substances, highest classifications)

- Carcinogen, Cat. 1B

- Mutagenic, Cat. 1B

- Reprotoxic, Cat. 1B

- phototoxic substance

- lipophilic (fat soluble)

„Limit values“:

- (depending on the individual substances)

- Acceptance concentration BaP: 70ng/m³ (0,00007mg/m³)

- Tolerance concentration BaP: 700ng/m³ (0,0007mg/m³)

- AGW naphthalene: 0.5 mg/m³ resp. 0.1 ml/m³

- Acute toxicity depends on the individual components, but must be classified at least as toxic.

Rules, guidelines, leaflets, implementation aids

- TRGS 524: Contaminated areas

- TRGS 551: Tar and other pyrolysis products from organic material

- DGUV regulation 101-004 (formerly BGR 128): Working in contaminated areas

- PAH notes: Guidance for the assessment and measures to reduce PAH contamination from parquet floors with tar adhesives in buildings

- BG - Instructions for the removal of PAH-containing adhesives for wood floors

- (withdrawn: LaGetSi PAH - Guidance for action).

Prohibitions:

- 1984 Ban on use in road construction

- 2000 Ban on use of anti-corrosion coatings

- 2002 Ban on use of wood preservatives (with exceptions)

Requirements for work with building materials containing PAHs:

- Building owner / client: duty to investigate (LBO; KrWG)

- Executing companies:

- Expertise for work in contaminated areas / building pollutants according to DGUV 101-004 6B and TRGS 524 2B for management and supervision

- Notification of the work to the employers' liability insurance association

6.7 PCB – Polychlorinated biphenyls

Vacuum cleaner

- Dust class H

Description

- Group of substances consisting of 209 different, artificially produced, organic chlorine compounds (C12H10-nCln; n>2).

- Properties of PCBs depend on their degree of chlorination,

- the higher the chlorine content the lower water solubility & volatility; the better accumulation in fatty tissue & more stable compound

- the lower the chlorine content the more volatile = high potential for secondary contamination due to attachment to particles, open pore materials; organic materials

- high flash point (170°C - 380°C)

- very good chemical resistance

- approx. 84,000t used in Germany

Occurrence

- permanently elastic joint sealants (no applications in the GDR); trade names: Thioko

- potting and filling compounds

- flame retardants and plasticizers in ceiling tiles

- paints and coatings

- Insulating oils in the electrical industry (transformers, capacitors ...); trade name: Clophen

- Plastics, e.g. cable sheathing

- Hydraulic fluids

- …

Health hazards

Record

- Resorptive

Health effects:

- Acute toxicity to be classified as toxic (category 3) by inhalation, dermal, oral ingestion, at a minimum, depending on degree of chlorination

- Eye irritation, Cat. 2

- Carcinogenic, Cat. 2

- Reprotoxic, Cat. 1B

- Specific target organ toxicity (nerve, immune system, liver)

- Bioaccumulative ("fat-loving").

„Limits“:

- MAK 0,003 mg/m³

Rules, guidelines, leaflets, implementation aids

- TRGS 524: Contaminated areas

- DGUV Rule 101-004 (formerly BGR 128): Working in contaminated areas

- PCB Guideline: Guideline for the assessment and remediation of PCB-contaminated building materials and components in buildings

- BGI/GUV-I 8665: Activities involving products containing PCBs

Prohibitions:

- 1978 Ban on open use (sealants, paints)

- 1989 Ban on use in Germany

- 2004 Ban on use in Europe

Requirements for work with building materials containing PCBs:

- Building owner / client: duty to investigate (LBO; KrWG)

- Executing companies:

- Expertise for work in contaminated areas / building pollutants according to DGUV 101-004 6B and TRGS 524 2B for management and supervision

- Notification of the work to the employers' liability insurance association

6.8 Metal dusts

Vacuum cleaner

- At least dust class M

- (Possibly additionally type 22)

- iPulse M-1635 Safe

- iPulse M-1635 Safe Plus

- ISC M-1625 Safe

Description

- Metal dust is generated during the working or processing of metal materials and building materials containing metals or their compounds

- Some metals or their compounds are considered carcinogenic!

- Metal dusts can be combustible / explosive!

- Metal dusts can oxidize on contact with acids or water and release hydrogen ("oxyhydrogen gas")!

- Metal dusts can oxidize with atmospheric oxygen!

Health hazards:

Carcinogenic metals or metal compounds

- Arsenic compounds

- Beryllium and beryllium compounds

- Cadmium and cadmium compounds

- Cobalt and cobalt compounds

- Chromium VI compounds

- Nickel compounds

- …

Combustible / explosive metals

- Aluminium

- Magnesium

- Iron

- Titanium

- Chroium

- …

Other health hazards depend on the individual substance, examples:

- Mercury: acute toxicity cat. 1; reproductive toxicity cat. 1B; specific target organ repeated exposure toxicity cat. 1; acute aquatic toxic effect cat. 1; chronic aquatic toxic effect cat. 1.

- Lead: Acute oral toxicity Cat. 4; Acute inhalation toxicity Cat. 4; Reproductive toxicity Cat. 1A; Lact.; Specific target organ repeated exposure toxicity Cat. 2; Chronic aquatic toxic effect Cat. 1

Rules, guidelines, leaflets, implementation aids

- TRGS 561: Activities involving carcinogenic metals and their compounds

- BGR 109: Grinding, brushing and polishing of aluminum

- DGUV Rule 109-011 (BGR 204); Handling magnesium

- GESTIS substance database:http://gestis.itrust.de

- GESTIS dust Ex database:http://staubex.ifa.dguv.de

6.9 Molds

Vacuum cleaner

- Dust class H

- iPulse H-1635 Safe Plus

Description

- Visible or non-visible mold growth or contamination indoors

- (Mold and mold spores are a natural part of the environment and thus are present everywhere!)

Cause

- Moisture and the presence of biological material is sufficient for mold growth

- Molds destroy organic material (e.g. wood).

Health hazards

- Depending on the mold, from harmless to highly toxic

- (Indoor molds are always an indicator of a problem/cause. If the cause of a mold infestation is not removed, an infestation will always recur!)

Rules, guidelines, leaflets, implementation aids

- Federal Environmental Agency - Guideline: For prevention, detection and remediation of mold infestation in buildings

- VdS 3151: Guidelines for mold remediation after tap water damage

- ...

Requirements for work on mold damage:

- Procedure

- Determination of cause

- Cause elimination

- Mold remediation

- Success control

- The work should only be carried out by appropriate specialist companies and accompanied by experts. Suitable experts and specialist companies can be found, for example:

- B.S.S. - professional association mold remediation e.V.

- B.V.S - Federal association of publicly appointed and sworn experts e.V.

- Network mold e.V.

- VDB - Professional Association of German Building Biologists e.V.

Vacuum cleaner

- At least dust class H

- iPulse H-1635 Safe Plus

Description

- From swelling fires to full fires and depending on the burned material, a large number of hazardous substances (at least PAH) and an impaired building fabric remain behind

Health hazards

- Biological health hazards depend on the material burned (plastics, wood, etc.), other building pollutants present (e.g. asbestos, PCBs, etc.) and the degree of combustion (complete or incomplete combustion).

- Physical hazards depend on the extent of the fire and the extinguishing measures taken

Rules, guidelines, leaflets, implementation aids

- TRGS 524: Contaminated areas

- DGUV Rule 101-004 (formerly BGR 128): Working in contaminated areas

- VdS 2357: Guidelines for fire damage restoration

Requirements for the restoration of cold fire areas

- Executing companies:

- Expertise for work in contaminated areas according to DGUV 101-004 6A and TRGS 524 2A for management and supervision.

- Notification of the work to the employers' liability insurance association

- For asbestos additionally:

- Expertise according to TRGS 519 for responsible and supervising person

- Approval as a specialist company for AS work on weakly bonded asbestos

- Notification of the work to the occupational health and safety authority (notification to the employers' liability insurance association)